Exploring Efficient Routes for Precious Metal Recovery from Complex Homogeneous Systems.

Dr Jamie Conway-Baker of Mastermelt UK discusses the collaborative approach to the problem of metals recovery from difficult waste streams.

Homogeneous catalysts are fast becoming the preferred catalyst choice over heterogeneous systems across multiple sectors such as Pharma, Agrochemical and Flavours and Fragrance (F&F). The global homogeneous catalyst market was valued at USD 4.4 billion in 2020 and is expected to reach USD 6.5 billion by 2026, growing at a CAGR of 6.5% during the forecast period.

Platinum, Palladium and Rhodium are typically used in the form of metal complexes consisting of the metal ion bound to one or more ligands. While these catalysts provide numerous advantages, their precious metal residues can be difficult to treat and refine, resulting in lower recoveries, challenging process economics, and environmental concerns. Additionally, strict regulations regarding the transportation of hazardous materials make managing these catalysts even more complex.

The precious metal is often the most expensive component of the catalyst therefore it is becoming ever more important to create an efficient, circular economy for such metals.

In this article, we will examine the factors that influence treatment routes, technology options, and how to maximize economic recovery with the assistance of a technology partner.

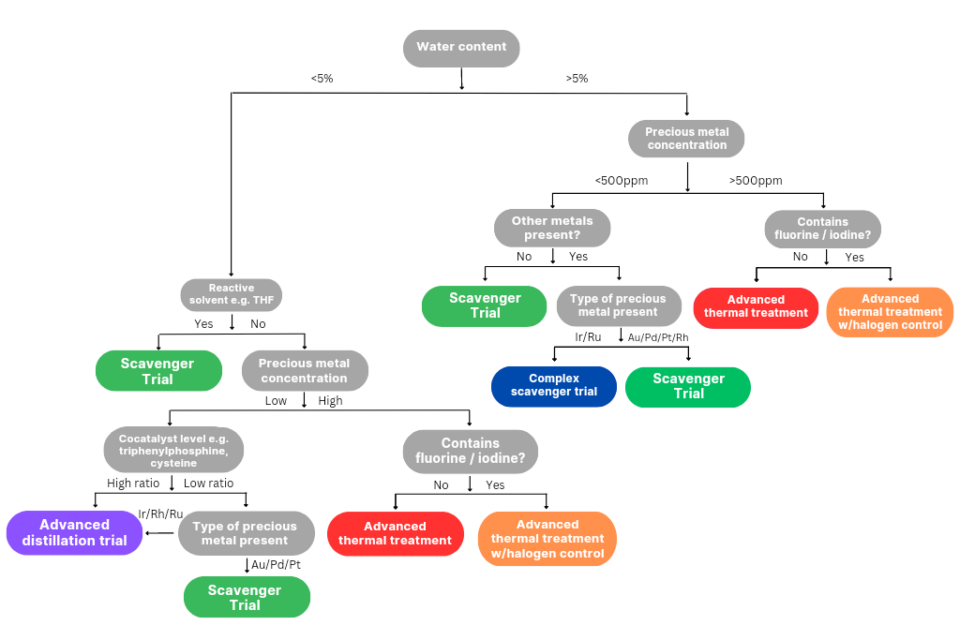

Fig.1 Primary treatment routes for homogeneous waste stream trials

Market Trends and Drivers

The key factors propelling the market’s expansion include:

- Growing demand for more efficient and sustainable chemical processes: Homogeneous catalysts offer higher selectivity and better conversion rates compared to their heterogeneous counterparts, leading to increased demand in various industries.

- Technological advancements: Innovations in catalyst design, synthesis, and characterization have enabled the development of novel catalysts with improved performance, further propelling the market’s growth.

- Increasing focus on environmental regulations: As the emphasis on reducing environmental pollution grows, companies are adopting homogeneous catalysts to create eco-friendly processes that comply with regulatory standards.

Treatment Route Factors and Technology Options

Several factors influence the choice of treatment routes and technology partners, such as solvent selection, co-catalyst choice, and the overall complexity of the material. Based on these factors, three primary technology options are available for catalyst recovery: Scavengers, Advanced Distillation, and Advanced Thermal Treatment. A summary of recovery routes is show in Fig 1:

- Scavengers are functionalized materials (polymers/silicas) that selectively bind to the precious metal in solution. These are often used in fixed bed columns, which can be installed on the processing site or treated off-site as a service.

- Advanced Distillation is a technique in which lower boiling point solvents are removed, leaving a concentrate or tar. Running a distillation process with the goal of recovering precious metals differs from standard solvent separations. Special conditions and additives are required to minimize losses.

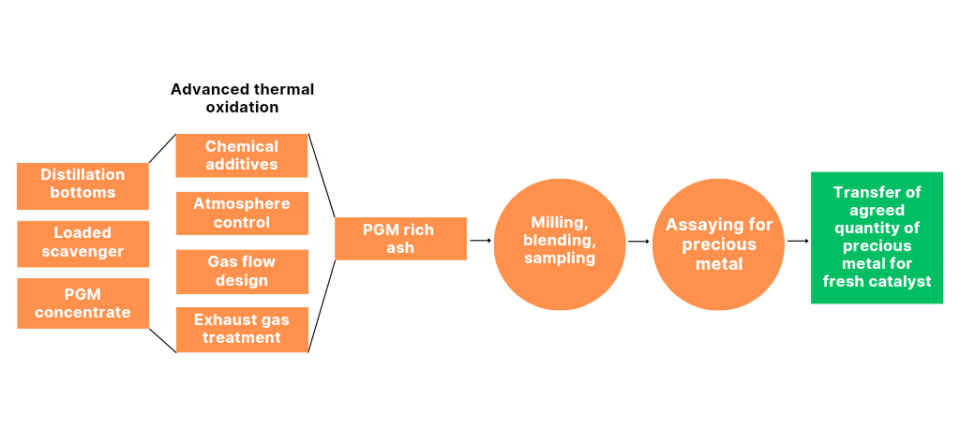

- Advanced Thermal Treatment involves removing water and oxidizing carbon-containing compounds to produce a rich ash. This process has significant complexities to ensure controlled oxidation. Off-gases must be treated by a suitable gas treatment plant to meet required emission standards. Some advanced thermal treatment systems can even process materials containing fluorine and iodine through proprietary technology development.

Fig.1 Recovery routes to Precious Metal return

Catalyst Characteristics

There are a number of characteristics which influence the optimum treatment route, examples include:

- Solvent: The choice of solvent is crucial in determining the treatment route. For example, solvents like tetrahydrofuran (THF) are undesirable for advanced thermal treatment due to their ability to form explosive peroxides, making it difficult to separate the catalyst from the solvent. On the other hand, low boiling point, unreactive solvents can be distilled off more efficiently.

- Co-catalyst and Segregation: Co-catalysts like fluorine, iodine, and triphenylphosphine can influence the treatment route. Proper segregation of these elements is essential to maximize recovery and minimize complications during the refining process.

The flowchart (Fig 2) can be used to suggest the primary treatment route to trial. The exact characteristics and process economics should be reviewed after initial test work.

Once the initial recovery has been completed, the processing of the precious metals should be carried out by a provider with proven expertise of the exact material type. There is a significant advantage in working with a technology provider who has expertise in all steps of the treatment.

Case Study

Mastermelt takes a multi-technology approach to homogeneous catalyst refining with expertise in Scavenging, Advanced Distillation and Advanced Thermal Treatment. During a customer review with chemical manufacturer, it became apparent that there was a significant stock of Rhodium homogenous catalyst residues on site. As the client run many complex synthesise for their products there was a significant variation of the types of residues including solvents, distillation bottoms, aqueous residues and solids. The client had tried to work with other precious metal refiners but none could offer a solution on these materials. With a strong collaborative approach, Mastermelt characterised the different material types and carried out development of different recovery process routes. Mastermelt assisted in successfully gaining the environmental permitting and transport before treating the catalyst residues using the technologies described in this article.

The client was and continues to be very happy with the outcome and look forward to continuing the partnership with Mastermelt.

Conclusion

In the rapidly expanding homogeneous catalyst market for precious metals, companies must address the challenges associated with the complex catalyst residues. By partnering with a technology provider that can collaborate and offer all technology options, there is a greater chance of success. A thorough understanding of the factors influencing treatment routes and technology options enables companies to make informed decisions that result in improved process economics, better environmental compliance, and enhanced circularity.

Utilising a customized flowchart as a decision-making tool can further assist in selecting the appropriate technology option based on catalyst characteristics and other factors. Ultimately, the right technology partner, combined with a comprehensive understanding of the market and available options, can pave the way for a more sustainable and economically viable approach to managing precious metal catalysts in the homogeneous catalyst market.